What is a connector

Electronic connector refers to the connection between various electronic components, mainly as the chip on the circuit board, circuit board and circuit board to the box of electronic signal connection and transmission. Category, can be divided into substrate connector, angle Connectors, cylindrical connectors, and the popular PCMCIA specification connector and so on.

Although the definition of electronic connectors has not been clear, the scope of its coverage, the general understanding does not include the power plug or socket other than the high voltage, high current electrical or electrical connectors: the electrical switch does not include the large in Japan Most of the people in the industry are directly transliterated in English, sometimes called "continuous". In mainland China, they use "electrical connectors" or "electrical connectors," including connectors and switches, In terms of applications, most of the electronic connectors are used in computers, telecommunications, aviation, automotive and various instruments above.

Application of the connector

Electronic connectors for electrical products, as the name suggests it is playing the electronic or component connection, is a multi-joint or assembly of products and cover metal sheet, surface plating, precision machining and plastic molding and other key technologies . As the transmission and connection of the electronic number, if the electronic connector has a problem, will lead to electronic components and even the entire equipment failure.The entire connector includes the terminal and plastic two main parts, the terminal part in addition to the selection of materials, electroplating and die Will affect the product quality, of course, the plastic part is the same reason.

Third, the connector manufacturing

The manufacture of electronic connectors from design to finished products, can be divided into metal and plastic parts.Metal parts in addition to material selection, electroplating and dies as the main work; mold work is the mold design, mold, injection Forming, and then with the metal components into a series of electronic connectors.Electronic devices for electrical products, as the name suggests it is playing the electronic signal or component connections, is a multi-joint or assembly of products and cover sheet metal, Surface plating, precision machining and plastic molding and other key technologies.As the transmission and connection of electronic signals, if the electronic connector problems, will lead to part of the addition to the selection of materials, electroplating and dies are good or bad will affect the quality of the product , Of course, the plastic part of the same Road, its manufacturing, including the five major technologies: 1. Die Technology 2. Injection molding technology 3. Electroplating technology 4. Assembly technology 5. Detection technology As the connector trend toward thin short and SMT, It is necessary for the manufacturing technology required to improve the accuracy of its requirements, while the precision of the manufacturers also need to change the concept of precision to create a connector, or in the end of the connector to the market, will be eliminated Out, because the quality of electronic components can not compete even the entire equipment failure. The entire connector, including the terminal and the plastic two main parts of the terminal.

Pin Header Series

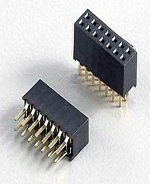

Pin Header Series Female Header Series

Female Header Series Jane cattle horns & Products

Jane cattle horns & Products Continental Connector DIN41612

Continental Connector DIN41612 Terminal Block Products

Terminal Block Products Other Products

Other Products